In partnership with WVIA, with support from Coterra Energy, we’re bringing you a look behind the scenes at some of Northeastern Pennsylvania’s most successful manufacturing operations. Join us as we get to know the companies, the unique products and the hardworking people leading the way in reestablishing NEPA as a driving force in global manufacturing.

Follow along on this 10-part series that explores NEPA @ Work.

130 Years of Textile Expertise

Gentex Corporation’s journey from its start as a silk yarn manufacturing company to becoming the nation’s leading provider of personal protective equipment is a remarkable story of innovation, craftsmanship and community. What began in the late 19th century has transformed into a global leader in safety and defense products, thanks to the hard work, ingenuity and dedication of its skilled workforce located right here in Northeastern Pennsylvania.

From Silk Fabrics to Artillery Bags

Founded in the 1880s in New York, the Klots Throwing Company, owned by Henry Durrell Klots, initially operated as a silk-throwing plant. After a fire destroyed the facility in 1884, Klots’ bookkeeper, Marcus Frieder, proposed tapping into an underutilized, readily available workforce: the largely unemployed wives and daughters of Northeastern Pennsylvania coal miners. Instead of rebuilding in lower Manhattan, Klots invested in a new location and moved the company to Carbondale, PA.

First World War

In 1914, following Klots’ death, Marcus became President of the company and by 1916 rebranded it as General Silk. When the United States entered World War I in 1917, Gentex shifted its focus to producing silk black powder cartridge bags for heavy artillery, marking its entry into the defense sector. This transition solidified its commitment to supporting military personnel.

The decline in silk consumption, the rise of less costly fibers, and the Great Depression in the late 1920s and early 1930s strained the silk industry, causing many of the finest textile companies to fail. Despite filing for bankruptcy, Marcus and his son, Leonard Peter, reorganized the company, renaming it General Textile Mills. Their expertise in textiles led to uniquely engineered products for high-performance applications, and once again, they were called upon to support the nation’s defense needs.

World War II and the First Hard Shell Helmet

The company’s experience in manufacturing silk cartridge bags laid the groundwork for future innovations and wartime assistance. General Textile Mills continued to evolve, developing large cargo parachutes for payload delivery and lightweight but durable containers to store them in.

The Government called on them in 1948 with a unique request – could they use the same textile composite from the parachute containers to manufacture helmets for fighter jet pilots? Thus, the first hard-shell helmet, known as the H-1, was born.

As they continued to diversify the business into protective products and technologies, General Textile Mills shortened its name to Gentex in 1958 to reflect their new business focus.

Military’s Go-To Engineering Company

Over the following decades, Gentex became renowned for its military and aviation helmets, consistently improving safety standards and incorporating cutting-edge materials. By the latter half of the 20th century, Gentex expanded its capabilities to develop and manufacture advanced respiratory products, as well as hearing and vision protection systems. Its commitment to research and development fueled growth and secured business with the United States military, along with numerous foreign defense and commercial aerospace customers.

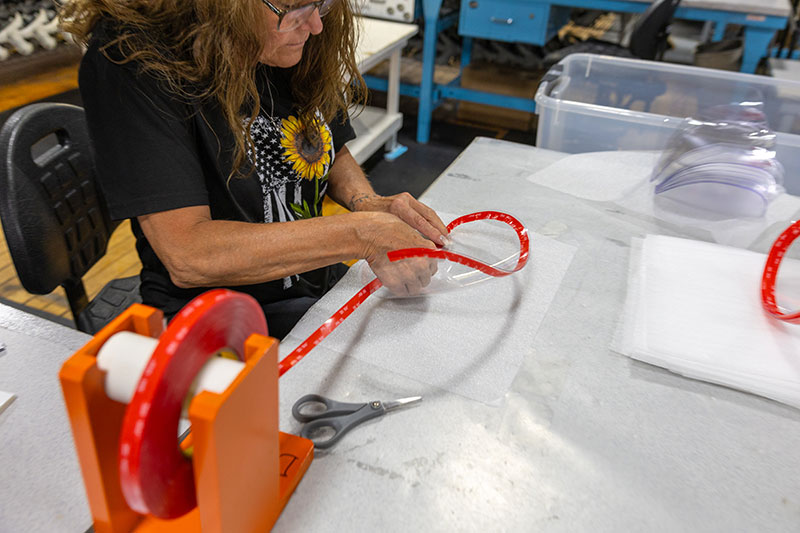

Carefully Hand-Crafted with Precision

With eight facilities across the United States, Europe and Australia, Gentex’s headquarters remains in Carbondale, Pennsylvania. This 300,000-square-foot plant employs over 600 people who specialize in the design, engineering, manufacturing and testing of protective gear for military, special forces, law enforcement and first responders worldwide.

Now in its fourth generation under L.P. Frieder III, Gentex emphasizes the craftsmanship behind its products. From the earliest stages of design and engineering through processes that include sophisticated precision molding, sewing, painting and final assembly, the local workforce has a direct hand in crafting each piece of equipment that safeguards America’s armed forces and emergency personnel.

Employees take pride in their work, knowing they contribute to life-saving solutions. Their meticulous attention to detail and recognition of the importance of what they do ensures that every product meets the highest standards.

“There’s a deep sense of pride in the work we do here. It’s fulfilling in ways other jobs aren’t. Whenever we hear stories from our end users, we share them with the team to remind everyone how vital their contributions are. Whether it’s cutting a helmet pattern or sewing a chinstrap, each task plays a crucial role. At the end of the day, they’re helping protect lives and ensuring people make it home safely.”

Veteran Expertise Driving Innovation and Safety

With a close connection to the end user, Gentex proudly employs veterans and former customers of their products. Their unique insights and experiences are invaluable in continuously improving life-saving equipment.

“At the core of everything we do is a strong focus on the end user,” emphasizes Brax. “We have a close relationship and feedback loop with them, allowing us to understand what they’re experiencing, identify emerging threats and anticipate future challenges from their perspective. To ensure authenticity in our designs, we also involve individuals with firsthand experience. This helps us speak their language, address their concerns directly and deliver solutions that truly meet their needs.”

Personal Protection and Situational Awareness Expertise

Gentex has evolved from silk manufacturing to personal protection and situational awareness, specializing in advanced helmet systems, oxygen masks, respiratory protection equipment, optical products and integrated communication systems. Its commitment to innovation and safety continues to support military and defense operations, solidifying its reputation as a trusted name in personal protective equipment.

Giving Back

Gentex Corporation is dedicated to giving back to the community, exemplified through their partnership with Camp Freedom in Carbondale. Camp Freedom provides outdoor adventures to veterans, first responders and their families to promote healing and camaraderie. Gentex supports this mission by donating resources and time, reinforcing their commitment to those who serve both in and out of uniform.

DiscoverNEPA and WVIA are proud to highlight the tremendous manufacturing organizations and opportunities within our region. We offer a special thank you to Coterra Energy for generously supporting this project.